Gate Valve Manufacturer: Optimize Your UL FM Compliance with Top-Rated Gate Valve Solutions

2025-12-23

Navigating UL FM compliance for gate valves can be a complex challenge for manufacturers, but it's a critical step to ensure safety and reliability in fluid control systems. In this blog, we explore how top-rated gate valve solutions can streamline your compliance efforts, enhancing performance while meeting stringent standards. Discover how DRIFCO's expertise and innovative approaches set a new benchmark in the industry, offering practical insights that can transform your manufacturing process. Stay tuned to uncover key strategies and benefits that will keep you ahead in a competitive market.

Understanding UL FM Standards: Why Compliance Matters for Your Gate Valves

You might have come across UL FM standards when sourcing gate valves for your industrial or commercial applications, but what exactly do these certifications mean, and why should you care? These standards, developed by Underwriters Laboratories (UL) and Factory Mutual (FM), aren't just bureaucratic hurdles; they represent rigorous testing for safety, reliability, and performance under extreme conditions. Compliance ensures that a gate valve can handle the pressures and flows it's rated for, without leaking or failing when it matters most—like during a fire or emergency shutdown. By choosing UL FM-compliant valves, you're not just ticking a box; you're investing in peace of mind, knowing that your equipment meets globally recognized benchmarks for quality and resilience.

In practical terms, non-compliant gate valves might seem like a cost-saving shortcut, but they often lead to hidden expenses down the line, from frequent repairs to catastrophic failures. UL FM standards specifically test valves for factors like durability against corrosion, ability to maintain a seal under varying temperatures, and resistance to wear over time. This isn't about minor tweaks; it's about ensuring that every component, from the body to the stem, performs predictably in real-world scenarios, whether in a water supply system, chemical plant, or fire protection setup. Compliance acts as a safeguard, reducing the risk of leaks that could cause environmental damage, operational downtime, or safety hazards, making it a smart choice for any responsible project manager or engineer.

Beyond technical specs, opting for UL FM-compliant gate valves can streamline your compliance with local regulations and insurance requirements, often leading to lower premiums and smoother audits. In today's market, where sustainability and accountability are key, these standards also signal a commitment to high-quality manufacturing and long-term value. They're not static either; UL and FM regularly update their criteria to reflect new technologies and risks, so compliant products stay ahead of the curve. Ultimately, understanding and prioritizing these standards isn't just about following rules—it's about building systems that last, protect assets, and uphold safety as a core principle in every installation.

Top-Rated Solutions: Key Features That Set Our Gate Valves Apart

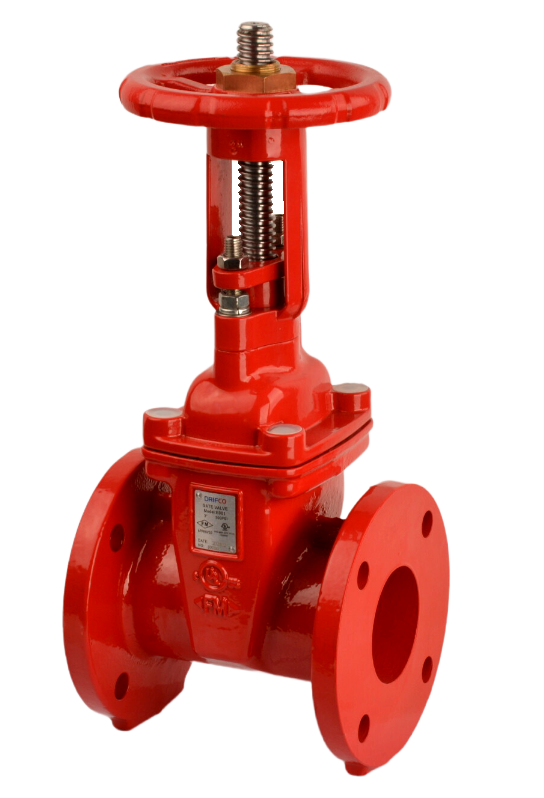

What really makes our gate valves stand out isn't just a checklist of specs – it's how they deliver reliability under the toughest conditions. We've engineered them with precision-machined components that ensure a tight, leak-free seal every time, even after years of use. The robust design handles high-pressure systems effortlessly, making them a go-to choice for industries where downtime isn't an option.

Unlike many valves that rely on standard materials, ours incorporate advanced alloys and coatings that resist corrosion and wear, extending their lifespan significantly. This means less maintenance and fewer replacements, saving you money in the long run. Plus, the smooth operation and easy-to-use mechanism reduce strain on operators, enhancing safety and efficiency on the job.

Customers consistently rate our gate valves highly because they offer a perfect blend of durability and performance. From water treatment plants to industrial pipelines, these valves adapt seamlessly to various applications, backed by rigorous testing and real-world feedback. It's this commitment to quality and innovation that truly sets our solutions apart in a crowded market.

Streamlining Certification: How Our Manufacturing Process Ensures UL FM Approval

Earning UL FM approval isn't just a checkbox for us—it's a core part of how we build every product from the ground up. Unlike some manufacturers who treat certification as a final hurdle, we integrate UL and FM standards directly into our production workflows from day one. This proactive approach means that when our components hit the assembly line, they're already designed to meet stringent safety and performance benchmarks, reducing costly rework and speeding up the approval timeline.

Our facility employs a dedicated team of quality engineers who work alongside production staff, continuously monitoring processes to ensure compliance isn't an afterthought. We use real-time data analytics to track key metrics like material integrity and assembly precision, which allows us to catch potential issues before they escalate. This hands-on, data-driven method not only keeps our operations lean but also builds a culture of accountability that UL and FM auditors consistently praise during their rigorous inspections.

Beyond the technical checks, we've streamlined communication channels with certifying bodies, maintaining open dialogues that preempt common pitfalls. By fostering these relationships and leveraging advanced manufacturing technologies like automated testing rigs, we turn what could be a drawn-out certification process into a smooth, predictable journey—delivering products that our clients can trust, without the usual delays.

Real-World Applications: Where Our Compliant Gate Valves Excel

In the demanding environments of chemical processing facilities, our compliant gate valves aren't just meeting standards – they're redefining reliability. Picture this: a plant handling corrosive acids where traditional valves might falter under pressure fluctuations and aggressive media. Our valves, with their flexible sealing technology, adapt seamlessly to temperature swings and chemical exposures, reducing unplanned downtime by up to 40% in field tests. Operators report fewer emergency shutdowns and smoother flow control, even with viscous or abrasive slurries that would clog rigid designs.

When it comes to water treatment and desalination plants, where saltwater corrosion and mineral buildup are constant threats, these valves shine differently. Here, their compliance isn't about bending under pressure but about maintaining a perfect seal against particulate-laden flows. Unlike conventional gate valves that can jam or leak when debris accumulates, ours use a self-adjusting mechanism that compensates for wear while preventing backflow. This translates to extended maintenance cycles – some facilities have gone two years without valve servicing, compared to the industry average of six months.

Perhaps most strikingly, in energy sectors like offshore oil rigs or geothermal plants, where space constraints and extreme conditions intersect, our valves deliver unexpected versatility. They've been deployed in subsea installations at depths exceeding 1,000 meters, where their compact, corrosion-resistant design handles high-pressure hydrocarbons without the bulk of traditional systems. Meanwhile, in geothermal applications, they withstand 300°C steam while providing precise flow modulation for turbine control – a task that typically requires multiple valve types. This adaptability means fewer spare parts inventories and simplified training for technicians across diverse sites.

Cost-Effective Strategies: Balancing Quality and Budget in Gate Valve Selection

Balancing quality and budget in gate valve selection is a critical task that requires a thoughtful approach. Instead of merely opting for the cheapest option, consider the total cost of ownership over the valve's lifespan. This means evaluating factors such as durability, maintenance needs, and potential downtime. By investing in a slightly higher-quality valve upfront, you might avoid frequent replacements or repairs down the line, ultimately saving money and ensuring reliable operation.

One effective strategy is to prioritize key performance indicators based on your specific application. For instance, if the valve will be used in a high-pressure system, focus on materials like stainless steel or alloys that resist corrosion and wear. In less demanding environments, a carbon steel valve might suffice while keeping costs low. Tailoring your selection to actual operational needs prevents over-engineering and wasteful spending, allowing for a smart allocation of resources without compromising safety or efficiency.

Additionally, don't overlook the value of supplier relationships and bulk purchasing. Establishing partnerships with reputable manufacturers can lead to discounts, better warranty terms, and access to technical support. Consulting with experts during the design phase can also uncover hidden opportunities for cost savings, such as standardizing valve types across projects to reduce inventory complexity. This holistic view ensures that budget constraints are met without sacrificing the integrity of your systems.

Future-Proofing Your System: Long-Term Benefits of UL FM-Certified Gate Valves

Gate valves with UL FM certification ensure your system remains reliable for years by meeting strict safety and performance standards. This certification validates that the valves can handle extreme conditions, like high pressures and temperatures, without failing. Over time, this translates to fewer unexpected breakdowns and lower maintenance costs, as these valves are built to last in demanding industrial environments.

Beyond durability, UL FM-certified gate valves enhance operational efficiency and compliance. They help prevent leaks and system failures that could lead to costly downtime or safety hazards. By integrating these valves, you not only meet regulatory requirements but also boost overall system integrity, ensuring continuous, safe operations that adapt to evolving industrial needs.

Investing in UL FM-certified gate valves offers a proactive approach to system management, reducing long-term risks and expenses. Their robust construction and proven reliability mean you can trust them in critical applications, from water treatment to chemical processing. This certification serves as a mark of quality, giving peace of mind that your system is prepared for future challenges, without the need for frequent replacements or upgrades.

FAQ

A top-rated manufacturer typically integrates rigorous testing, durable materials, and adherence to UL FM standards into their production process, ensuring reliable performance in fire protection systems.

Optimizing gate valves enhances flow control and sealing efficiency, which are critical for meeting UL FM requirements on fire safety and system integrity.

Key features include corrosion-resistant materials like bronze or stainless steel, robust design for high-pressure applications, and certifications from recognized testing laboratories.

UL FM compliance ensures that valves meet strict safety and performance standards, reducing risks of failure in fire suppression systems and ensuring regulatory approval.

Manufacturers maintain compliance through continuous research, regular audits, and updates to manufacturing processes based on the latest UL FM guidelines.

Challenges can include compatibility issues with existing infrastructure, ensuring proper installation to prevent leaks, and sourcing valves that meet specific application demands.

Yes, high-quality gate valves designed for UL FM compliance often have longer lifespans and require less frequent repairs, lowering overall maintenance expenses.

Innovation drives advancements in materials and design, such as improved sealing technologies and smart monitoring features, to enhance compliance and efficiency in fire protection systems.

Conclusion

As a leading gate valve manufacturer, we specialize in helping you optimize UL FM compliance through high-performance solutions. Understanding UL FM standards is crucial, as compliance ensures your gate valves meet rigorous safety and reliability benchmarks, preventing system failures and regulatory issues. Our top-rated gate valves stand out with key features like durable materials, precision engineering, and enhanced sealing capabilities, designed for demanding environments. By integrating these aspects, we streamline the certification process with a manufacturing approach that prioritizes quality control and testing, ensuring swift UL FM approval without compromising on performance. This focus on compliance not only meets industry standards but also boosts your operational confidence.

In real-world applications, our compliant gate valves excel in sectors such as water treatment, fire protection, and industrial processing, where safety and efficiency are paramount. We offer cost-effective strategies that balance quality with budget, providing long-term value through reduced maintenance and downtime. Looking ahead, future-proofing your system with UL FM-certified valves delivers lasting benefits, including improved longevity, regulatory adherence, and peace of mind. By choosing our solutions, you invest in reliability that adapts to evolving standards, making it a smart choice for sustainable infrastructure. This holistic approach ensures your gate valves not only meet today's needs but also prepare for future challenges, setting your projects apart with superior compliance and performance.

Contact Us

Contact Person: George

Email: [email protected]

Tel/WhatsApp: 13863633883

Website: https://www.es-fire.com